EN 388:2016+A1:2018 – Modification to the standard for cut protection gloves

Protection classes for cut protection gloves were previously assigned in Europe in accordance with standard DIN EN 388:2003. Due to the continuous development of technical materials – so-called "high-performance fibres" – it has become necessary to adjust the methods used to test and classify these products. These changes have been implemented in standard EN 388:2016+A1:2018.

EN 388:2003 test procedure

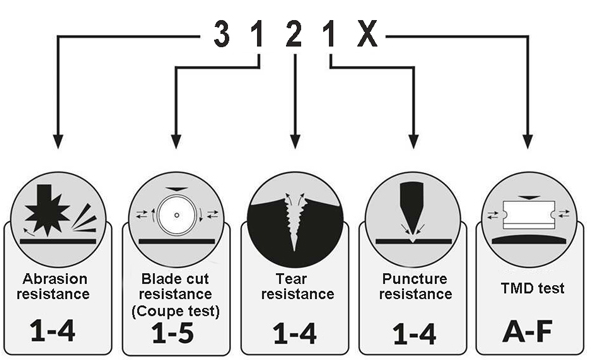

1. Cut resistance test using the coup test.

2. Rotating circular knife moves back and forth at a constant force (5 newtons) on the test material and rotates counter to the movement.

3. The index value results from the number of cycles required to the point at which the test piece is cut through, and from the degree of wear of the blade.

4. Five measurements are performed in this way on each test piece.

5. The average of the five index values confirms the corresponding performance class for the cut protection level of a safety glove.

EN 388:2016/ISO 13997 test procedure

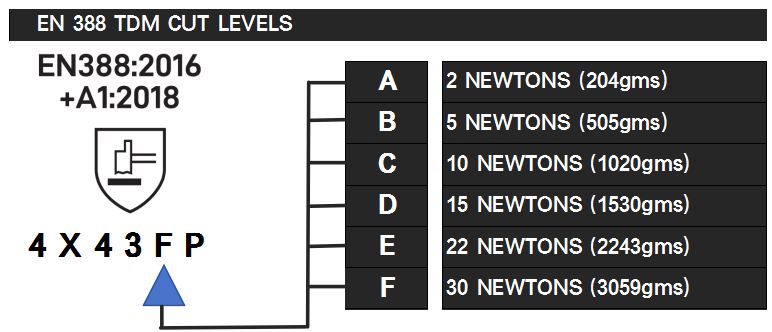

1. Relates to cut protection gloves made from materials that cause the blades to become blunt (i.e. glass and steel fibres).

2. Additional test procedure in accordance with ISO 13997: Determination of resistance of the glove to cutting by a sharp object through single contact under higher force.

3. A long, straight blade is drawn once over the test piece. The minimum force required to cut through the test piece after 20 millimetres is determined in the process. The result is given in newtons (N) and assigned to a cut protection class.

EN 21420: 2020- General Requirements for Safety Gloves

EN 420 is the basic overarching standard that defines general requirements for safety gloves. Whilst it doesn't outline specific protection and resistance levels, it does include basic guidelines that all gloves must meet.

These basic guidelines for safety gloves are:

1. The gloves themselves should not impose a risk or cause injury.

2. The pH level of the gloves should be as close as possible to neutral.

3. Leather gloves should have a pH value between 3.5 and 9.5.

4. The highest permitted value for chromium is 3mg/kg.

5. Details of any substance used in the glove that is known to cause allergies should be specified.

EN 374 – Protection from chemical risks

Chemical safety gloves must meet the requirements of European standard EN ISO 374-1. This standard has undergone fundamental changes in terms of certification.

Part 1 (Terminology and performance requirements for chemical risks) contains important modifications:

1. Expansion of test chemicals from 12 to 18

2. Omission of beaker glass for “water-resistant safety glove with low protection against chemical risks”

3. Standardisation of types of gloves into type A, B or C

4. Modification to labelling on the product: Pictogram of Erlenmeyer flask with differing number of letters for test chemicals depending on type

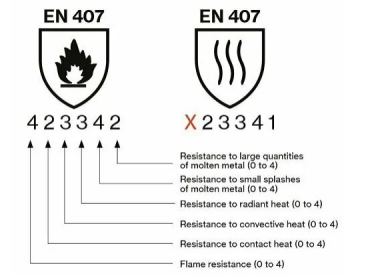

EN 407 –Safety gloves against thermal risks

The European standard DIN EN 407 regulates the minimum requirements and specific test methods for safety gloves in relation to thermal risks. Safety gloves certified in accordance with this standard protect the wearer from, for example, contact heat, radiant heat and small splashes from molten metal.

However, it does not concern the specific application of heat-resistant gloves, such as firefighting or welding. Heat-resistant gloves are intended to fulfil the following properties in accordance with DIN EN 407:

1. low flammability or flame spread

2. low heat transmission (protective effect from radiant, convective and contact heat)

3. high temperature resistance

Important changes to EN 407 standard

In the latest version of DIN EN 407: As of 2020, the first performance class is no longer named “resistance to flammability”, but is now called “limited flame spread”. If the glove has not been tested for this, a new pictogram is used (see above right). However, there are no changes to the performance classes. The test described in DIN EN 407 assigns safety gloves a performance class in relation to each of the individual thermal hazards. It is important that the glove does not come into contact with open flames if it does not meet the criteria of performance class 3 in the limited flame spread test.

EN 511 – Protection from cold

Minimum requirements for safety gloves in relation to protection from cold are regulated in standard DIN EN 511. The gloves certified under this standard are intended to protect the wearer from convective cold (penetrating cold) and contact cold (direct contact).

As with protection from thermal and mechanical risks, the safety glove is classified into different performance levels for individual aspects. The performance levels are indicated with a number from 1 to 4 next to the pictogram, where 4 is the highest level.

Determination of performance levels for safety gloves against cold:

Convective cold:

Measuring the quantity of energy needed to maintain the temperature of a heated hand model (30 to 35 °C) with a safety glove in relation to a constant room temperature. (Calculation of the thermal insulation properties based on the temperature of the hand model, room temperature and energy required to maintain the temperature.)

Contact cold (Test in accordance with ISO 5085):

Determination of thermal resistance of the safety gloves with a cold and a hot plate. The glove material is placed as an insulator between both plates and the change in the temperature gradient acts as a measurand (comparison with normative reference).

The glove can also be tested for water permeability in accordance with EN ISO 15383. If no water permeates into the glove over a 30-minute period, this test is deemed as passed (no specific performance levels).